Bangkok,Thailand

9AM – 5PM

support@mysteamengineering.com

Hot Line

Expanding your business

Mysteam engineering

Complete system solutions tailored just for you

We can help you to save your energy.

Improve your plant efficiency and performance with us today !

In manufacturing industries, steam and fluids play a vital role in various operations, including heating, cooling, power generation, and transportation. However, inefficient or outdated systems result in energy wastage, decreased productivity, and increased operational costs.

That’s where our expertise in steam and fluids engineering comes in.

STEAM & FLUIDS sYSTEMS ENGINEERING

Manufacturing Transformation Consultancy

pRODUCTS AND SERVICES

15 +

Years

Experience

WHY CHOOSE US

OUR EXPERIENCE IN APPLICATIONS

- Feedwater Conditioning

- Steam Generation

- Steam Distribution

- Steam Heat Exchange

- Condensate Return

- Heat Recovery

- Clean & Pure Steam

- Humidification

- Sterilizers , Autoclaves

- Tanks and Vats

- Rotating Cylinders

- Tracing

- Planing your Future Better

- Financial planing for safe investment

- Experience a brand new financial attitude

- Your financial matters according our plans

Equipment Selection & Installation

Selecting the right equipment is crucial for achieving optimal performance. We guide you in choosing the most suitable boilers, heat exchangers, pumps, valves, and other components. Our team ensures seamless installation and integration of new equipment into your manufacturing processes.

We are passionate about promoting sustainable practices within the manufacturing industry. Our experts employ advanced techniques to improve energy efficiency, reduce waste, and minimize environmental impact. By implementing energy-saving measures, you can significantly cut operational costs while contributing to a greener future.

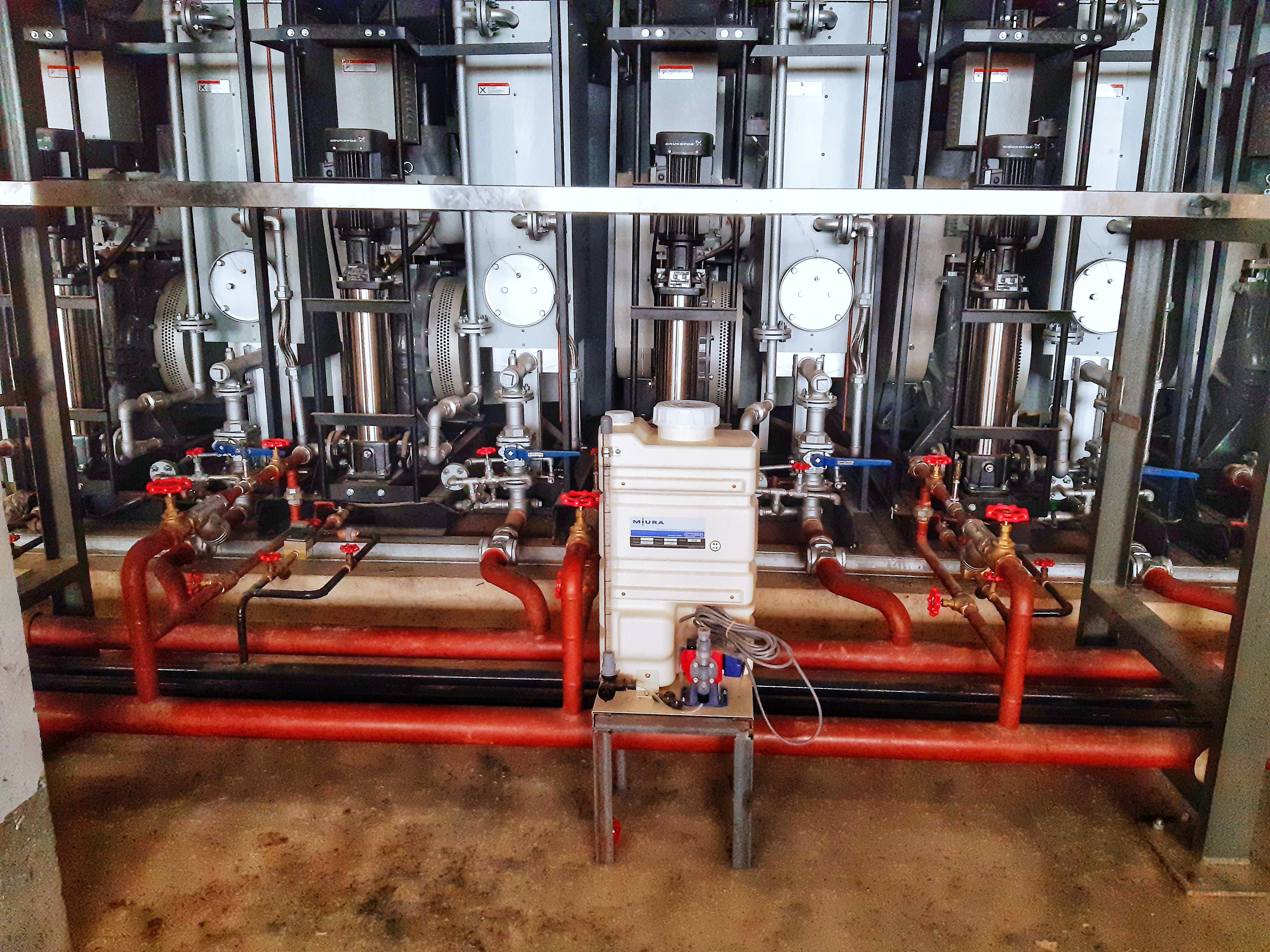

Oil and Petrol Chemical OPC

Oil and petrochemical plants have very specific steam system applications and we can work with you on reducing energy use , improving your plant’s performance and increasing profit.

We specialize in designing steam and fluid systems that are tailored to your specific needs. Our engineers carefully analyze your existing infrastructure and processes to identify areas for improvement. By optimizing your systems, we help you achieve better energy utilization, reduced emissions, and increased productivity.

We offer comprehensive maintenance services to ensure your steam and fluid systems continue to operate at peak performance. Our team conducts regular inspections, troubleshoots any issues, and provides swift repairs. Additionally, we provide ongoing technical support to address any queries or concerns you may have.

How Can I Help You

Your results are our top priority!

Expertise and Experience

Our team comprises seasoned professionals with extensive knowledge in steam and fluid engineering for manufacturing industries. We have a track record of delivering successful projects across various sectors.

Innovative Technology

We stay up-to-date with the latest advancements in steam and fluid engineering, incorporating innovative technologies to optimize your systems and processes.

Commitment to Sustainability

We are committed to helping our clients achieve their sustainability goals. Our solutions focus on energy efficiency, waste reduction, and environmental responsibility.

Our High Valued Services

We provide the best services

Up-Stream System Energy Saving and Utilization :-

Down-Stream System Energy Saving and Utilization

Steam Quality and Dryness

How Can I Help You

Giving Values To

your Manufacturing Business

CONTROLS AND INSTRUMENTATION

We can provide automated solutions to those customers with the systems expertise and also supply the relevant product and entire services required. Our solutions range from straightforward single loop control to SCADA systems ( allowing convenient monitoring , control , alarm handling and data logging ) and Fieldbus arrangements for digital communications ; allowing greater integration and flexibility in the way our customers run their plant.

- Monitoring control

- Data logging

- Alarm handling

- Digital communications

- SCADA systems

- Automated solutions

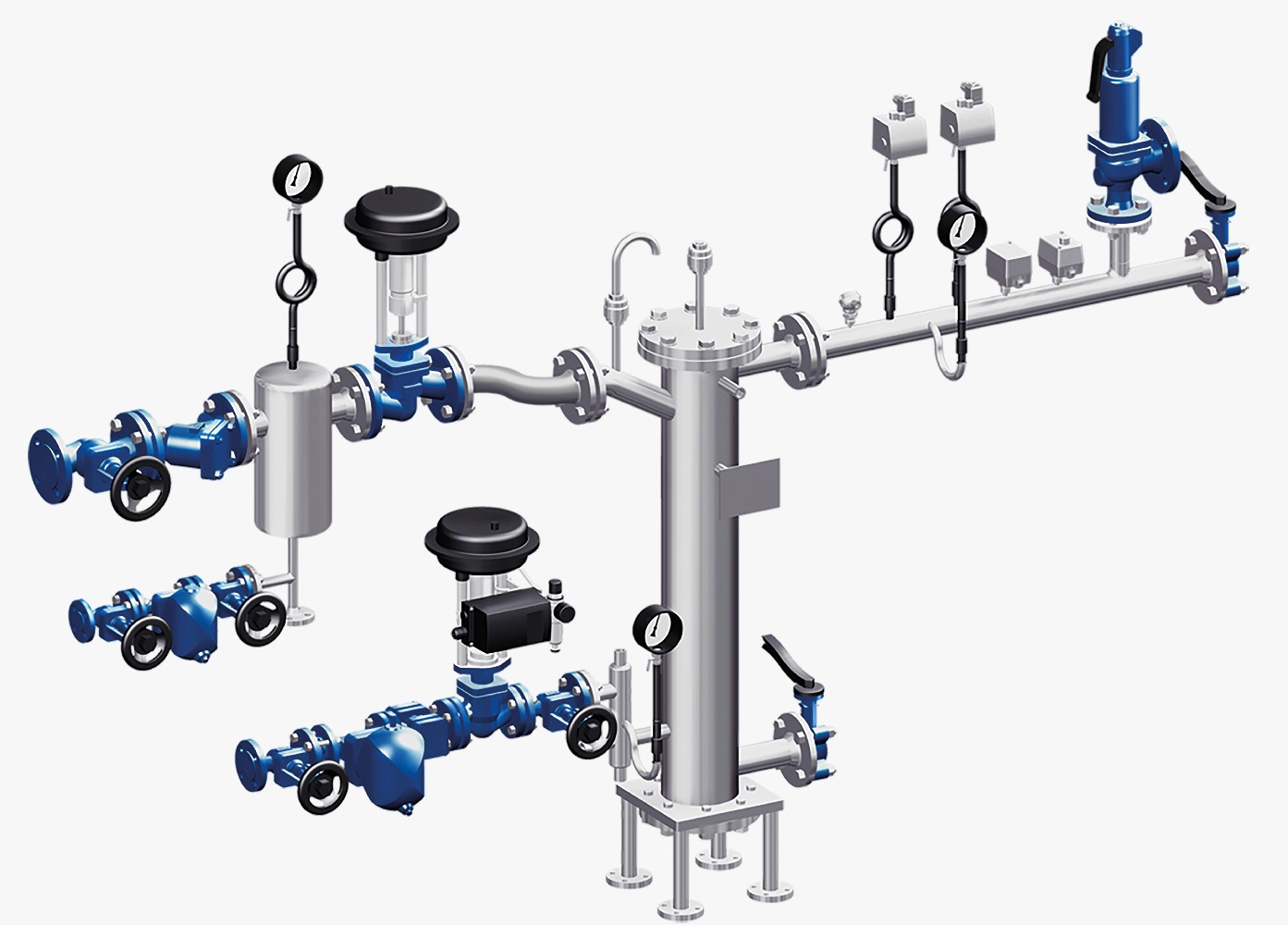

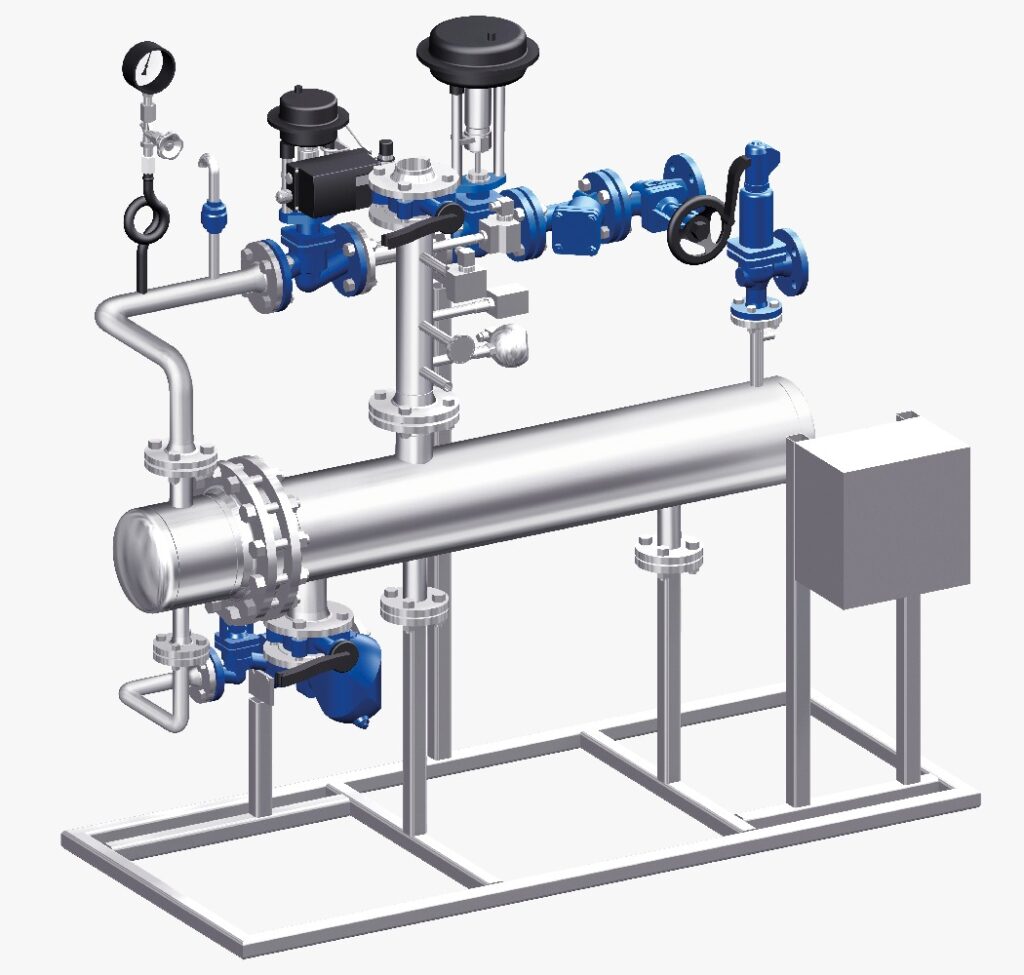

HEAT EXCHANGE SOLUTIONS

Our customers are concentrating increasingly on their core business and now rely on us to provide them with effective, well-engineered packaged solutions for their heat exchange needs.

Our heat exchange solutions are ready to install, incurring minimum downtime and installation expense , and allowing optimum ongoing performance . We can also offer bespoke packages to suit your exact requirement.

OIL AND PETROLCHEMICAL (OPC)

Oil and petrochemical plants have very specific steam system applications and we can work with you on reducing energy use , improving your plant’s performance and increasing profit.

MANUFACTURING TRANSFORMATION CONSULTANCY

The Smart Industry Readiness Index (SIRI) was created in partnership with a network of leading technology companies, consultancy firms, and industry and academic experts. SIRI comprises a suite of frameworks and tools to help manufacturers – regardless of size and industry – start, scale, and sustain their manufacturing transformation journeys. SIRI covers the three core elements of Industry 4.0: Process, Technology, and Organisation.

Our Energetic Members

Over 15 years of experience in the related steam and fluids industry. Engineering Design specialism and expertise to sizing, energy saving calculations, system utilization, ROI and payback analyzation and varies with specific requirements based on client’s business sizes.

Ray

Technical Consultant

Experienced field in sales playing as a key person , managing director at German Leading company , Eagle Burgmann. Over 30 years experienced with rich knowledgeable in high end engineering. High Management to smooth dealing with clients and top rated client’s satisfaction.

Ananvit Homchan

Director , Sales

An experienced professional in emerging markets, specializing in business strategy, market-entry, and enhancing efficiency in Industries 4.0.With a 20-year of experience at Siemens, Key positions in Vietnam and Thailand. Successfully implemented automation and digitalization frameworks, guiding customers across industries in emerging markets.

Christian Beckers

Certified SIRI Assessor

Director, Business Development

Energetic , keen learner relating renewable and sustainability. Experienced Roles in Project management ,operation and supervising skilled in Steam and Fluids related industrial field.

Julie Wai

Sales Engineer

AT OUR COMPANY

“We understand that every manufacturing facility has unique requirements and challenges. Our team of skilled engineers works closely with clients to develop customized solutions that enhance efficiency, reliability, and safety while minimizing downtime and maintenance costs.”

Get in touch with our team today. We are here to answer your questions, provide consultations, and collaborate on transforming your manufacturing operations into more efficient, sustainable, and cost-effective systems.

Ready to enhance your manufacturing processes with our steam and fluids engineering expertise?